Stevenson High School’s MADE Program trains the next generation of manufacturers with help from community partner Zero Tolerance and Cimatron.

As the industry continues to grapple with an ongoing shortage of experienced workers, high schools that offer specialized trade education and the community partners who support them play an important role in training the next generation of manufacturers.

For staff at Stevenson High School of Sterling Heights, Michigan, preparing future manufacturers for the workforce requires the right combination of teaching skill, educational resources, and the ability to recognize and foster passion for the industry.

“While some of our students are college bound, many are trade bound and leave with numerous certifications — whether it be for welding, machining, or robotics,” said Mark Lacombe, an instructor and academy coach for Stevenson High Schools’s Manufacturing, Automation, and Design Engineering, or MADE, program. “We show our students why school is valuable and what to expect after graduation — and provide them with some pathways they can take when they graduate.”

Part of the Utica Community School District, Stevenson MADE is a four-year program in which students choose from one of three dedicated learning pathways: automation, design engineering, or fabrication — including options to study welding and CNC machining. The program’s 12 instructors teach course work that connects standard high school core subjects — namely math, science, social studies, and English — to the field of advanced manufacturing through real-world connections and participation in project-based learning.

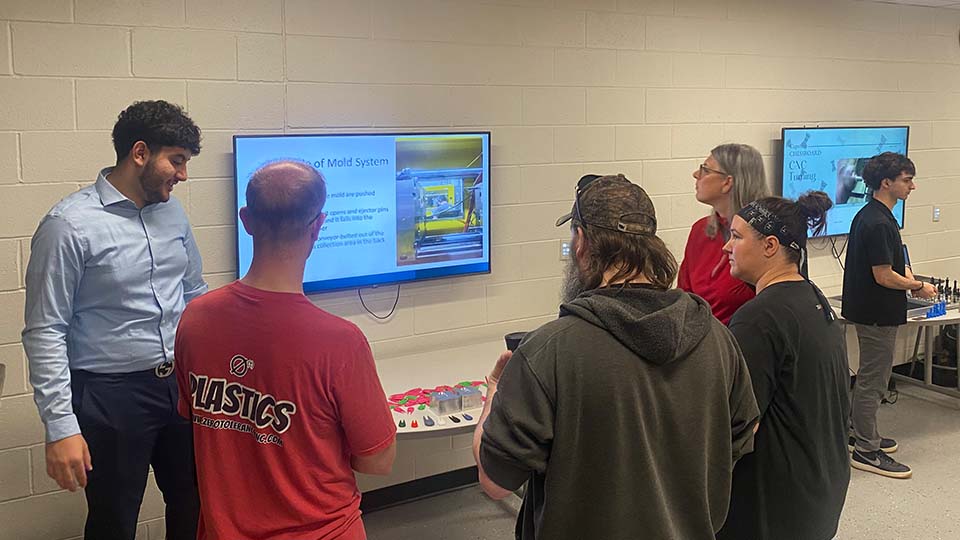

Community partners like Zero Tolerance, an injection-molding specialist in Clinton Township, Michigan, help Stevenson MADE by providing students with opportunities to gain vital practical knowledge and by offering guidance and jobsite experience.

“We’ve seen some lights turn on for young people while working in our shop, and it’s exciting to see because my interest in manufacturing began in high school, as well,” said Steve Michon, owner of Zero Tolerance. “I’m excited to pass that experience on, and there is a very real need for that in the industry because we see a lot less interest in going into the industry compared to what there used to be.”

Murphy Forsyth, injection molding manager at Zero Tolerance, discovered Stevenson MADE in roughly 2021, when she was searching for part-time workers to help in the company’s molding department. Zero Tolerance has since volunteered time and resources to work with students on projects, as well as hired high-school interns and graduates. The company, which was named Stevenson MADE’s partner of the year in 2024, has proved an ideal community partner.

“Every single student I've hired has been hungry to learn and fun to work with,” Forsyth said, adding that all shops should be as eager as Zero Tolerance to become involved with vocational training. “As workers retire, it’s important to think about who will be next to run your shop. Young people are interested and available to work, but we have to make the effort to find them, help them learn, and get them to where we need them to be in this industry.”

“We’ve been very lucky to work with a company that wants to be as involved with the program as Zero Tolerance,” Lacombe said. “Murphy walks into our shop and is friendly with all the kids. It’s like she’s part of our staff now.”

We’ve seen some lights turn on for young people while working in our shop, and it’s exciting to see because my interest in manufacturing began in high school, as well.

Stevenson MADE serves roughly 360 students in grades nine through 12, the majority of whom attend the school because they are interested in studying engineering or manufacturing.

“We’re fortunate to have industry-grade equipment with all the bells and whistles representative of what really happens in industry,” Lacombe said.

Since Stevenson MADE’s inception, its students represent a fairly even mixture of young men and women. The debut graduating class was comprised of 52% male and 48% female students. Regardless of the discipline studied, seniors complete capstone projects that demonstrate the skills they’ve learned in the program. Among these are the senior molding project, for which students focus on molding with help from staff at Stevenson MADE and Zero Tolerance.

“Working on a company-driven project for the last six or so months of their senior year gives them real-world experience that’s so different from school and so different from just cranking out their senior-year electives and being done with it,” Lacombe said.

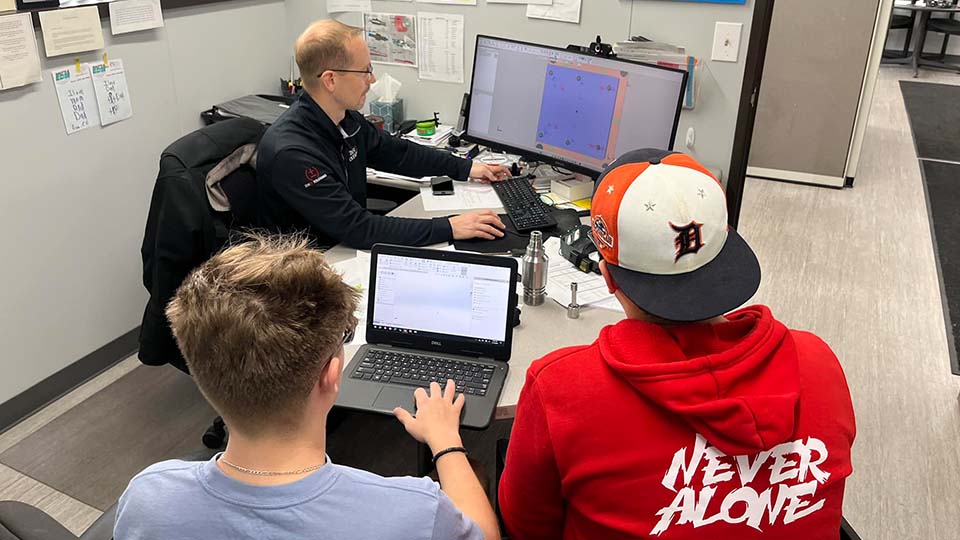

When the senior molding project was in its concept stage, its organizers discovered that students struggled to use the software at their disposal to design and produce injection molds.

To resolve the issue, Michon and Forsyth enlisted the help of their software provider, Cimatron — which develops dedicated CAD/CAM software for mold and die manufacturing. Upon learning about the program’s needs, Cimatron donated its software to Stevenson MADE to ensure that the next generation of manufacturers have access to the tools needed to prepare them for the workforce. Cimatron also donates software training for the program’s instructors to help them leverage the software as a teaching resource.

“Our intent is to help the industry, and to help Stevenson MADE and Zero Tolerance help the industry, by supplying them with the best possible resources for their students,” said Ralph Picklo, director of U.S. sales for Cimatron.

This is the future. We need skilled workers in manufacturing and that has to happen whether or not we’re part of making it happen — but I believe we need to be part of making it happen

The molding projects entail students designing parts to be produced via injection mold, then reverse engineering the molds based on the final parts and — finally — bringing their creations to life when the parts are produced using plastic injection machinery at Zero Tolerance.

“We start off with a simple mold base and the parts they design are simple, but they learn about parting lines and other important mold characteristics,” Michon said. “We’re trying to help them see the big picture as quickly as possible and giving them tools like Cimatron helps us explain how everything comes together much more easily.”

A student’s participation in a senior molding project can ignite a passion for the industry and influence their career plans.

“Most kids don’t know what injection molding is or that it’s a career option, so having that hands-on experience is unique and very cool,” Lacombe said. “Our goal is that every student has this same kind of relationship and experience with a company as they have with Zero Tolerance.”

Stevenson MADE’s academy model has proven so successful that Lacombe and his peers are frequently visited by staff from schools both domestic and international interested in implementing similar programs.

“There is such a need for workers in the Metro Detroit area that it just made sense to first choose the manufacturing route, but we're working on opening some other academies in our district,” Lacombe said. Among those are a newly established healthcare academy at another district high school, and expansion into additional vocations is on the horizon.

“This is the future,” Michon said. “We need skilled workers in manufacturing and that has to happen whether or not we’re part of making it happen — but I believe we need to be part of making it happen.”

Company: Zero Tolerance

Location: Clinton Township, Michigan

Website: www.zerotolerancecnc.com

Business: Designing and building plastic-injection molds, injection molding, sinker EDM burning, 5-axis machining, 3D plastic and metal printing, CMM inspection, fast hole wire EDM, and more

Zero Tolerance, LLC, is a growing plastic-injection mold machine shop that invests in high-performance machinery and tooling, as well as in personnel willing to go the extra mile to deliver exceptional customer service.

“We succeed in the production mold industry because of our willingness to improve and learn new things,” said Steve Michon, owner. “Keeping up to date with the latest software, machinery, and tooling helps us produce outstanding work.”

Michon has been designing, creating, building, and brainstorming since day one. He was the kid who created a hands-free light switch by designing a contraption to turn the light on in the morning when his alarm went off using a “dancing flower, string, tape, and eight AA batteries.”

His love of problem solving, research, learning, and the pursuit of perfection led to the founding of Zero Tolerance, a company guided by the principle of reaching success by taking chances while “aiming small and missing small.”

Today, Zero Tolerance tests the limits of materials by leveraging design expertise and years of experience in plastic injection molding to craft well-designed, premium quality, functional products for a variety of industries.

Stevenson High School's MADE Program, in collaboration with Zero Tolerance and Cimatron, is training the next generation of manufacturers through hands-on experience and industry partnerships to address the skilled worker shortage.

WeForm, בהיענות לדרישות גדלות של לקוחות, השקיעו בתא ייצור HSC אוטומטי לחלוטין המשלב כרסום 5 צירים ותוכנת CAD/CAM של סימטרון לייצור יעיל של חלקי יציקת פלסטיק ואבץ באיכות גבוהה בתעשיות שונות.

Everstampi, חברה בבעלות משפחתית במיסינטו עם יותר מ-40 שנות ניסיון בתכנון וייצור תבניות פלסטיק, בולטת בחדשנות ובהתמקדות בשירות הלקוחות, תוך שימוש בפתרונות CAD/CAM מבית סימטרון על מנת לייעל את תהליך התכנון ולהבטיח ייצור תבניות מורכבות ומדויקות.

Classic Tool & Die, בשימוש בתוכנת ה-CAD/CAM המתקדמת של סימטרון, השיגה עלייה של 75% בפריון והקטינה את טביעת הרגל הפחמנית שלה, תוך התמודדות מוצלחת עם פרויקטים מאתגרים של עיצוב מבלטים וטיפוח חדשנות עם יצרני OEM לרכב.

עקבו אחרינו ב־