By virtualizing Cimatron and setting up viewer stations, we’ve seen a 75% increase in productivity in floor assembly and reduced our carbon footprint compared to our previous process of plotting drawings and bringing them to the shop floor.

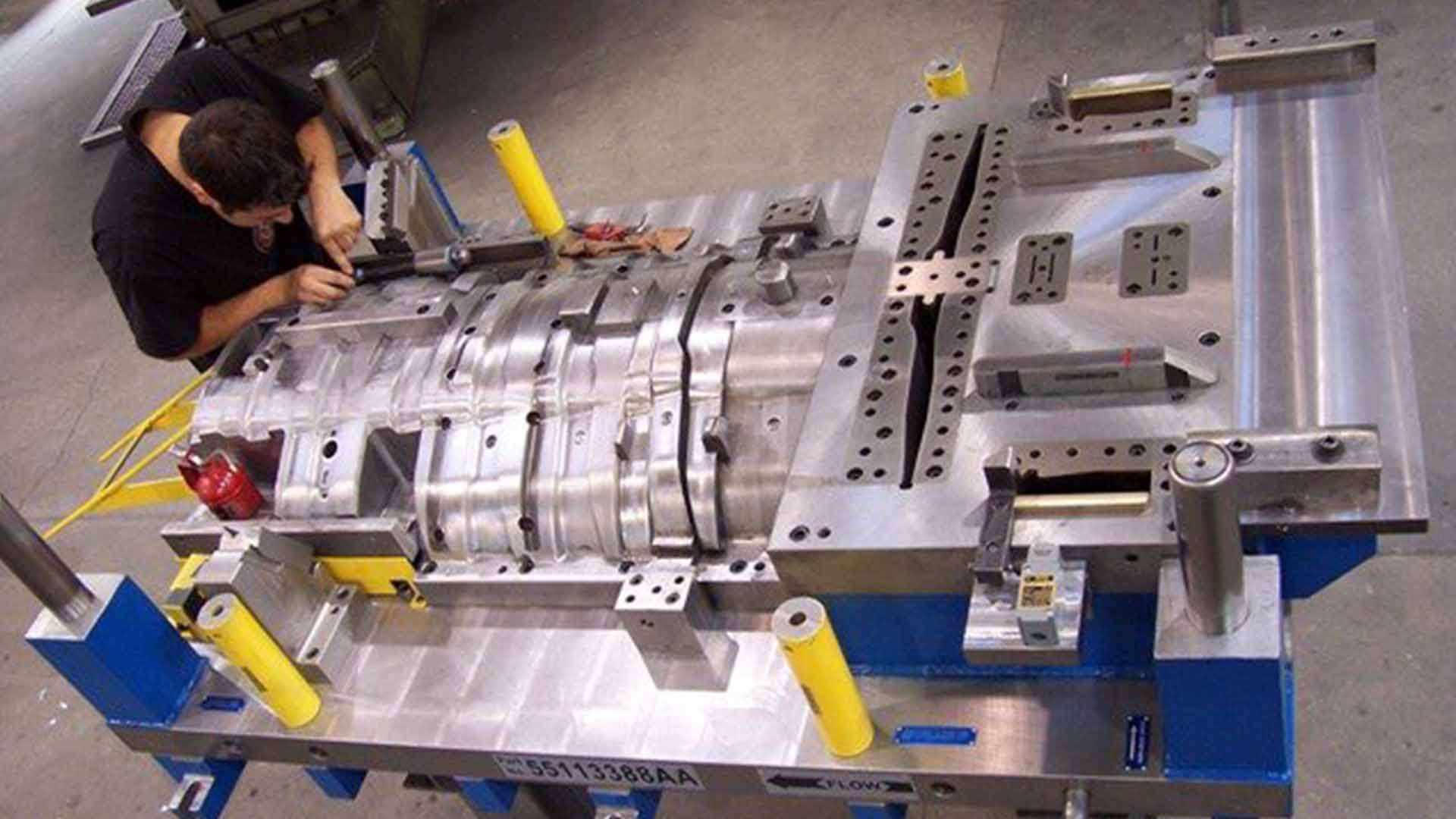

For 46 years, family-owned Classic Tool & Die has been providing customized stamping die solutions to a diverse range of industries, including automotive, aerospace, medical, architectural, and agricultural. With 30 employees operating out of a 30,000 sq. ft. facility in Windsor, Canada, Classic Tool & Die is known for tackling challenging projects and delivering turnkey solutions encompassing product development, die design and build, and part production.

“We pride ourselves on being a medium-sized tool and die shop with very large capabilities,” said Adriano Oppio, VP of Classic Tool & Die. “Our key focus is on providing not just run-of-the-mill tools or dies, but complete turnkey solutions encompassing everything from product development to final part production.”

When an automotive OEM approached Classic Tool & Die with an experimental project involving the explosive forming of a firewall, Oppio and his team knew they were facing a formidable challenge. The customer needed to form a steel panel using a single-draw die while maintaining consistent binder pressure throughout the stroke—a feat previously deemed impossible by pneumatic experts due to the inherent characteristics of gas compression, which increase as the die closes. Additionally, the binder pressure had to remain constant regardless of press speed, adding further complexity to an already daunting task.

Oppio and his team recognized the high stakes involved, as failure could jeopardize Classic Tool & Die’s relationship with the OEM. However, the company was determined to take the risk, pushing the boundaries of die design and hydraulics in the process.

“We contacted a lot of other experts in the field, and they said, ‘You can’t do it. It’s physically impossible,’” he recalled. “We went back to the OEM and said, ‘Okay, it’s going to be a struggle, but we’re willing to take a big risk and experiment.’”

Despite skepticism from others, Classic Tool & Die forged ahead, confident in its ability to innovate and find a solution. The team knew that success would not only solidify their relationship with the OEM but also establish the company as a leader in tackling the most challenging projects in the industry.

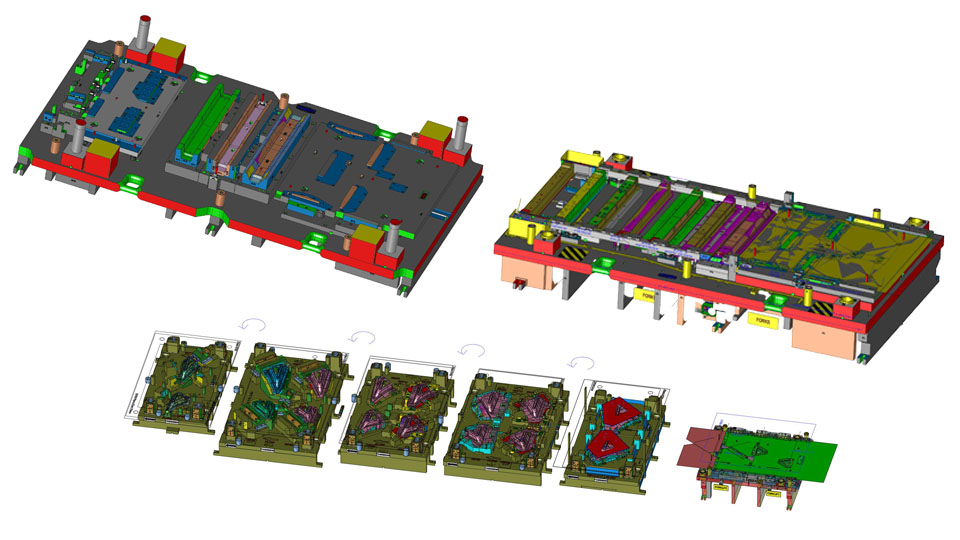

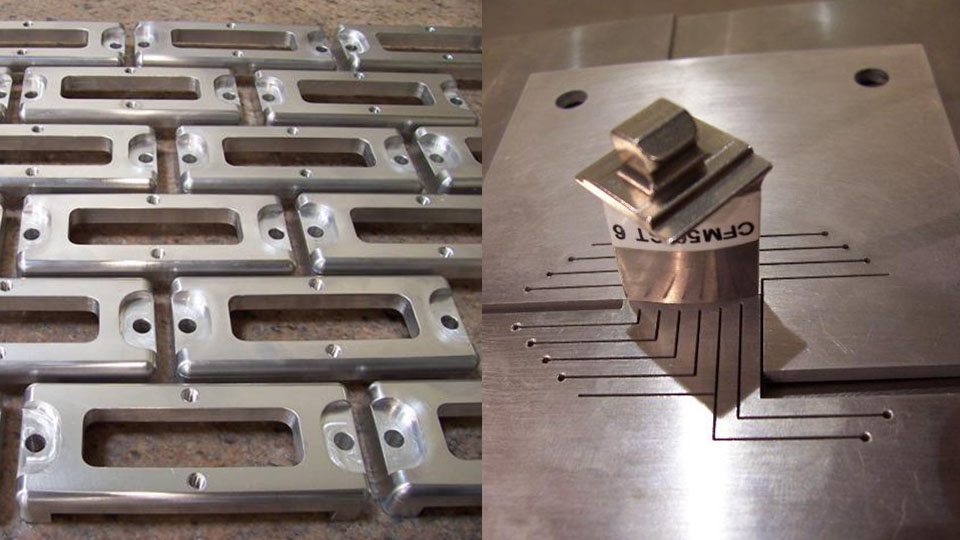

Classic Tool & Die turned to Cimatron CAD/CAM software to help it tackle this ground-breaking project. Using Cimatron’s powerful surfacing, scanning, and reverse engineering capabilities, Oppio and his team designed an innovative, hydraulically-controlled binder system capable of automatically adjusting pressure throughout the stroke. The team worked through three major tool and hydraulic system design iterations before achieving success.

The company collaborated with the University of Windsor on the project, tapping into the expertise of researchers and engineers to help refine their design and overcome the technical challenges. Meanwhile, the OEM handled the formability simulations, providing valuable insights into the material’s behavior and the die’s performance.

By virtualizing Cimatron and setting up viewer stations, we’ve seen a 75% increase in productivity in floor assembly and reduced our carbon footprint compared to our previous process of plotting drawings and bringing them to the shop floor.

In addition to the hydraulic challenges, the part presented complexities due to its massive size and varying draw rates across the different areas. Classic Tool & Die had to ensure that the draw pad maintained consistent motion throughout the process, a critical factor in achieving the desired part quality and preventing defects.

“Cimatron’s surfacing, in conjunction with reverse engineering and scanning, really helped us with this project,” Oppio noted. “The software’s capabilities allowed us to iterate on our designs and find the optimal solution quickly.”

To further streamline their processes and improve efficiency, and shift towards greener solutions, Classic Tool & Die virtualized Cimatron and deployed viewer stations on the shop floor. This allowed die makers to access 3D models and drawings on large screens right next to the die, eliminating the need for physical drawings and reducing the risk of errors.

“By virtualizing Cimatron and setting up viewer stations, we’ve seen a 75% increase in productivity in floor assembly and reduced our carbon footprint compared to our previous process of plotting drawings and bringing them to the shop floor,” Oppio explained.

Cimatron’s seamless integration with Classic Tool & Die’s CNC machines was crucial to the project’s success. Operators could directly access part details and the entire die design on the machine controller, eliminating data translation issues and ensuring they always had the most up-to-date information for machining.

“We’ve built Cimatron die design libraries for different customers and requirements, including metric and imperial standards, as well as progressive and transfer die configurations,” Oppio added. “This helps us streamline our processes and deliver high-quality tools and dies more efficiently.”

Classic Tool & Die’s willingness to take on this “impossible” project — and its successful execution using Cimatron software — opened the doors to a long-term, innovation-driven partnership with the automotive OEM. The cutting-edge hydraulic binder system, which allowed for varying pressures during the draw process, led to two patents and paved the way for annual experimental projects and further patent development.

“It completely opened the doors for this OEM moving forward,” he shared. “Now, we do an innovation project with them every year, and patents have been developed because of the projects we’ve created.”

The success of this initial project demonstrated Classic Tool & Die’s ability to push the limits of die design and hydraulics, solidifying its reputation as the go-to partner for challenging, innovative projects. The company’s relationship with the OEM has since grown to include six major projects, each building upon the foundation laid by that first experimental tool.

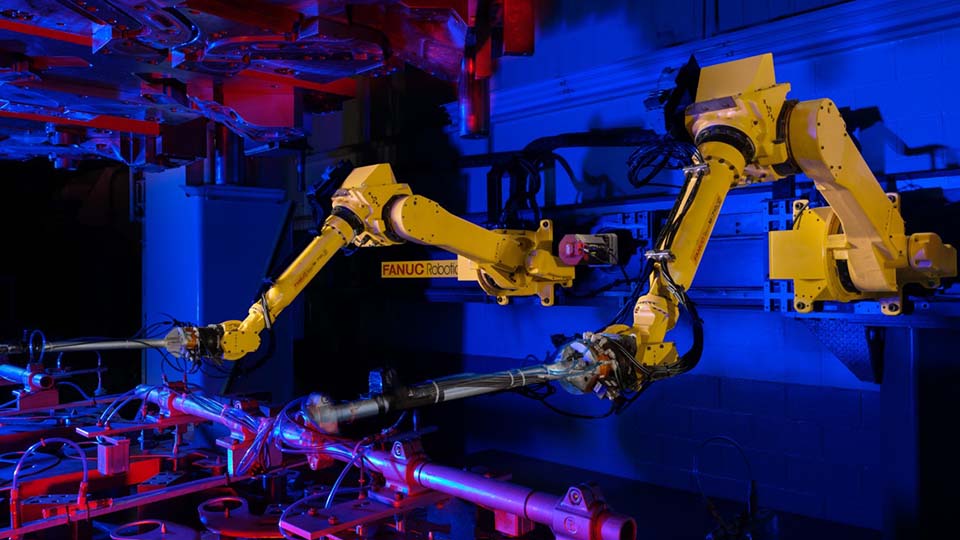

Looking to the future, Classic Tool & Die continues to innovate and expand its capabilities. The company recently installed a large 1500-ton Danly press with a 96” x 212” bed and a full robotic transfer system. This addition allows it to offer specialized services for low-volume production runs and emergency jobs, further enhancing its ability to provide comprehensive solutions to its customers.

“With our new press and transfer system, we can take on even more challenging projects and provide a wider range of services to our customers,” Oppio explained. “It’s all part of our commitment to delivering the best possible solutions and staying at the forefront of the industry.”

Classic Tool & Die remains dedicated to fostering innovation, collaboration, and continuous improvement. And with Cimatron as a key partner in its success, the company is well-positioned to tackle future challenges and continue delivering exceptional results for its customers.

With Cimatron by our side, we’re confident in our ability to take on whatever challenges come our way and continue pushing the boundaries of what’s possible in the tool and die industry.

ComplexaHPE utilizes Cimatron CAD software to design intricate molds for the medical industry, enhancing efficiency and precision in producing complex tooling needed for various medical components.

Stevenson High School's MADE Program, in collaboration with Zero Tolerance and Cimatron, is training the next generation of manufacturers through hands-on experience and industry partnerships to address the skilled worker shortage.

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Follow us on