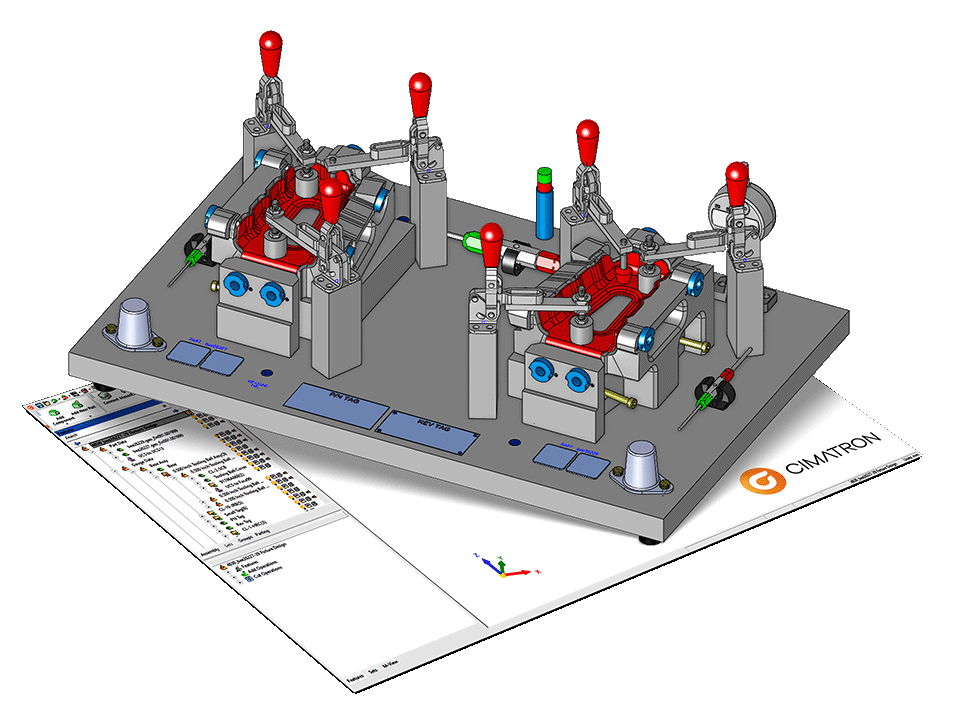

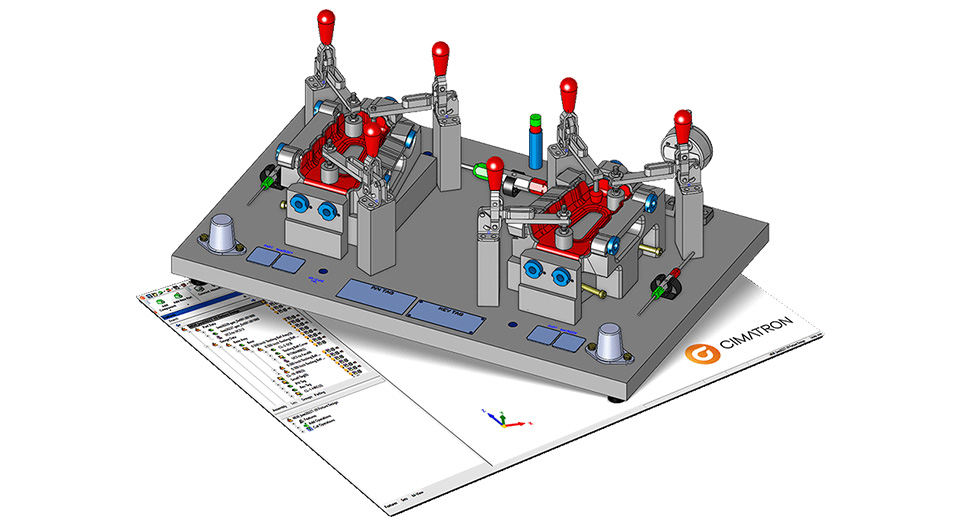

Cimatron CAD provides a flexible 3D parametric hybrid modeling environment that integrates history-based and direct edit design tools, enhancing productivity with exceptional design flexibility.

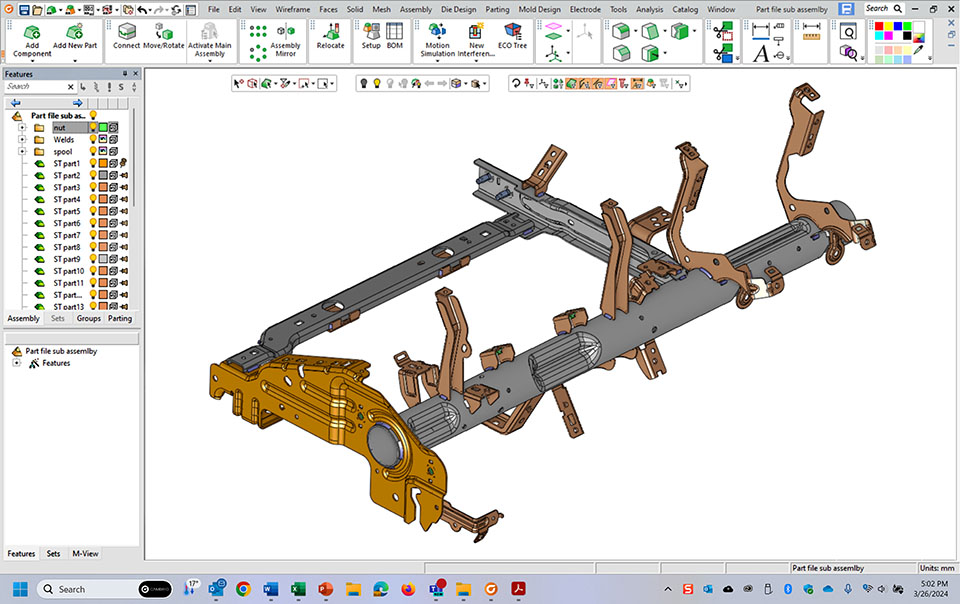

Users can take advantage of powerful dedicated design features such as advanced solids and surfacing modeling, robust assembly tools, and fully associative 2D drawings/BOM, with comprehensive support for concurrent design and ECO management.

Download Brochure

Choose the best technique for the job from among hybrid solid and surface modeling tools.

Eliminate error at the design stage with a range of tools that verify the integrity of in-progress designs.

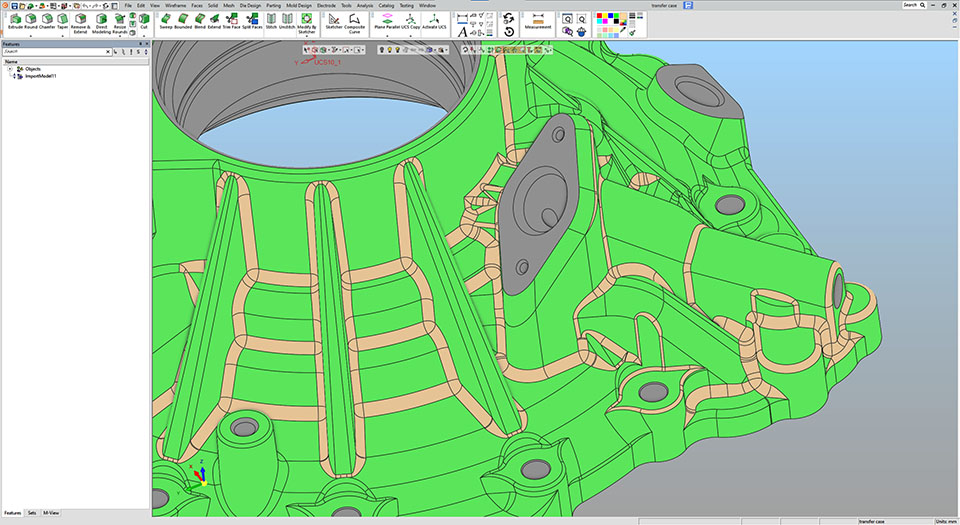

Use analysis and editing tools to quickly prepare part designs for efficient CNC programming.

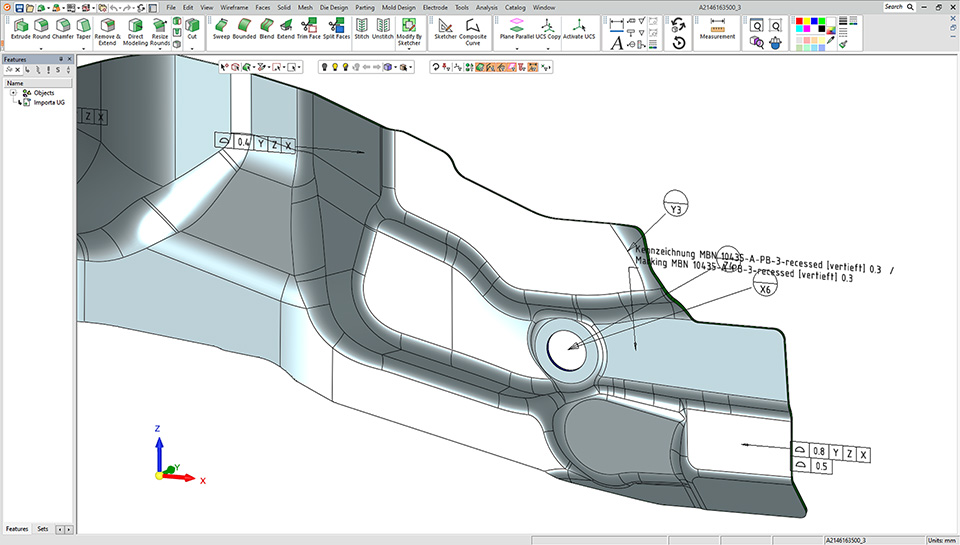

CIMATRON CAD makes it easy to work with 3D CAD data in all standard file formats and offers direct translators for OEM CAD data, including vital product manufacturing information (PMI). Designers can take advantage of model-based definition (MBD) capabilities to add PMI and geometric dimensions and tolerance (GD&T) data for streamlined production. Native Cimatron don’t require data translation and can be efficiently shared with customers.

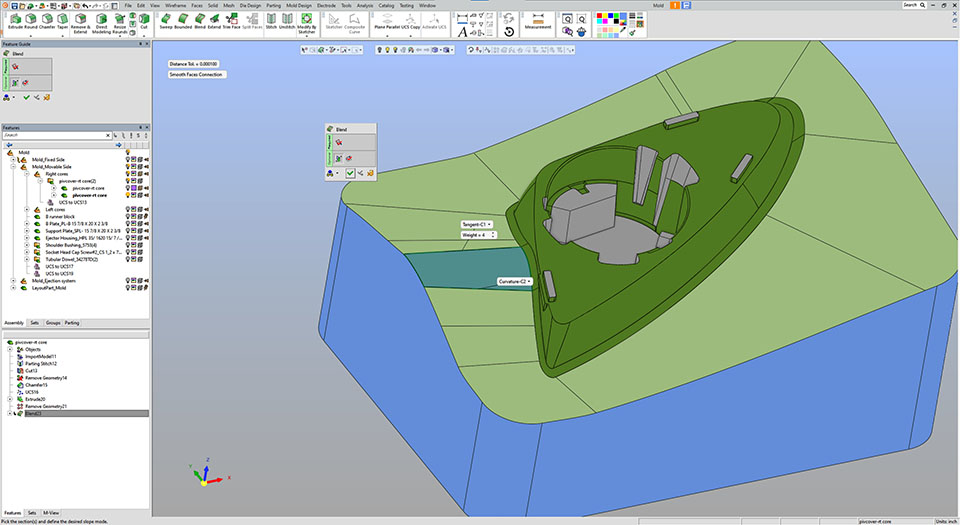

Hybrid solid and surface modeling capabilities increase efficiency and flexibility by enabling designers to choose the tools that work best for them — and for the job. Functions for working with solid models include direct modeling capabilities that simplify the creation of holes, ribs, rounds, chamfers, and tapers. Changes can be applied at any time during the design process using hybrid, history-based, and direct modeling tools.

Cimatron includes powerful tools for surfacing, wireframe creation, and editing. To simplify the design of complex assemblies, designers can source supplier components from a range of catalogs, add them to designs, and easily duplicate components.

Use interference checking, cut verification, and integrated motion-analysis tools to increase efficiency at the design stage by eliminating the errors that require rework.

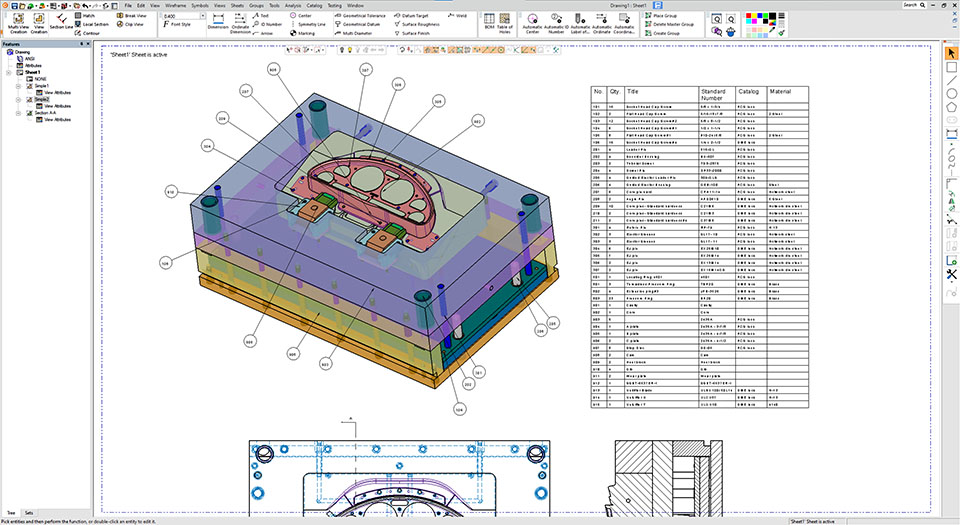

With a click of the mouse, 2D drawings that are associative with bills of materials (BOMs) can be automatically created from 3D parts and assemblies.

Prepare part designs for efficient CNC programming using analysis and editing tools that accelerate the transition to production. Draft angles can be applied and relevant areas capped before sending jobs to the shop floor.

Follow us on