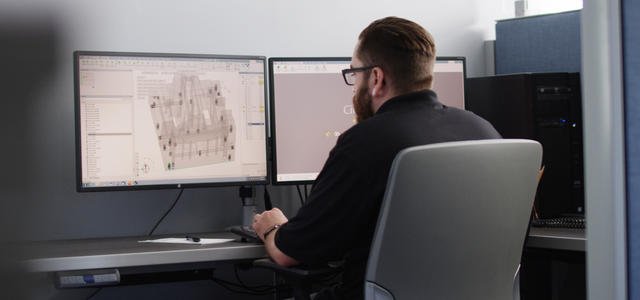

Cimatron® integrated CAD/CAM software for mold design and manufacturing

In this business, time is money. Something that used to take us 16 weeks to build, we can now build in 10–12 weeks using Cimatron.

ComplexaHPE utilizes Cimatron CAD software to design intricate molds for the medical industry, enhancing efficiency and precision in producing complex tooling needed for various medical components.

Stevenson High School's MADE Program, in collaboration with Zero Tolerance and Cimatron, is training the next generation of manufacturers through hands-on experience and industry partnerships to address the skilled worker shortage.

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

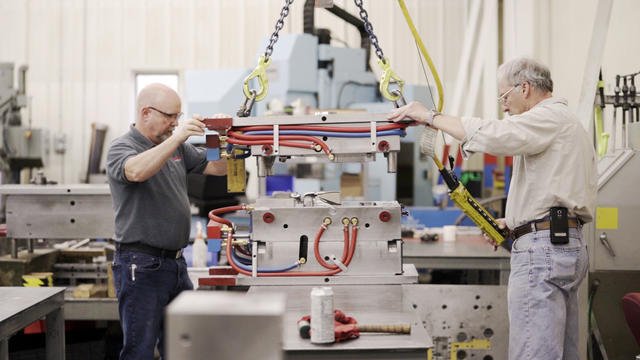

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Follow us on