Formed in 2021 as an engineering excellence group by Managing Director Paul McHugh, the company combines the expertise of Complexatools — a mold designer and manufacturer founded in 1987 — with that of High Precision Engineering (HPE) Limited, an engineering and manufacturing specialist founded in 1996.

“Over the years, we’ve accumulated extensive industry knowledge that can be applied to every aspect of mold design and manufacturing,” McHugh said.

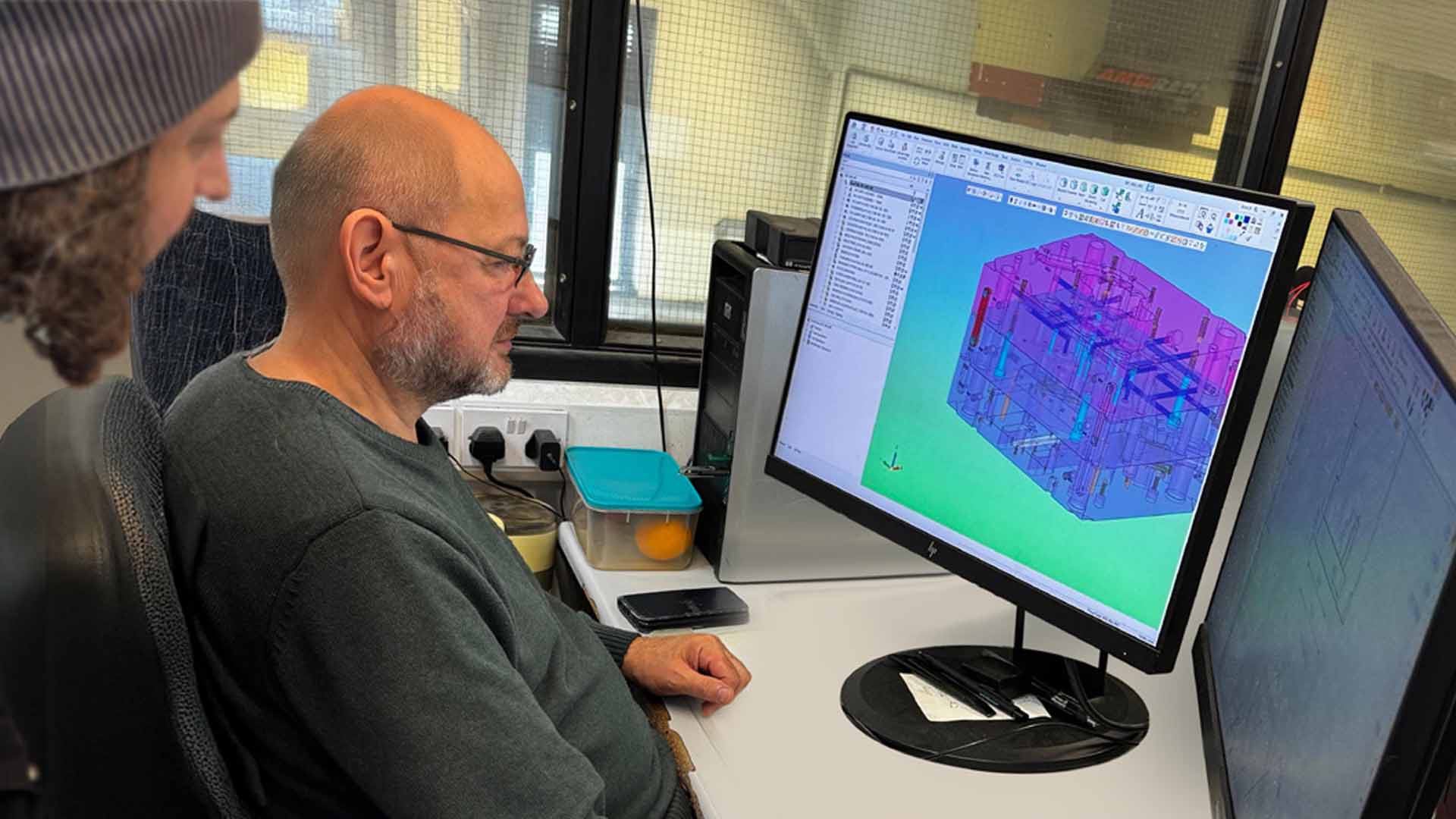

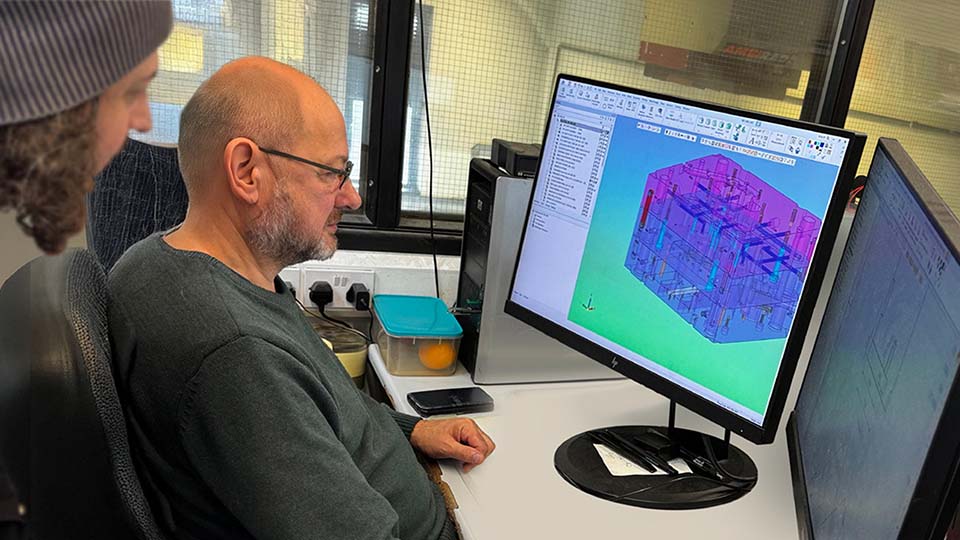

ComplexaHPE employs a team of roughly 46 personnel who turn out precision molds from sites in Glossop, Ashton, and Rochdale — areas with rich manufacturing heritage. Since its inception, the company has used Cimatron CAD software to design sophisticated tools capable of molding flawless parts from challenging materials and withstanding the rigors of high-volume production. The complex class 101 medical molds the company designs and manufactures produce components like laboratory equipment, surgical instruments, diagnostic devices, and implants such as knee joints.

We can put the new model into our existing tool design and then update the entire model in a way that saves a lot of time... that’s a process I don’t think other software could do as easily.

“Cimatron has a lot of features that specifically help with mold design,” said Designer Jack Bunting, who has used Cimatron for more than 12 years. Among features noted for being especially helpful is a wizard that enables users to jumpstart design by simply entering information into a standard data form.

“Once you’ve worked out how you want to create the tool around the part, it gives you the first step for creating the base of the tool, which can be done in as little as five minutes,” Bunting said. “I tell the system the number of plates I want on the fixed and moving halves and assign the plates a specific size and thickness. From there, I just click a button, and it uses that information to create a 3D model.”

Designer Richard Capener, who has used Cimatron for over 20 years, automates laborious data entry to significantly reduce design time and opportunity for error. Leveraging Cimatron’s flexibility, Capener adapted configuration files to ensure important part data is automatically linked to part drawings.

“The software works the way you want it to work, rather than just as a standard package,” Capener said. “You can develop a configuration that picks up detailed attributes when you create text within a drawing so that it assigns attributes — like type of steel and surface finish — to the parts you’ve drawn.”

The software works the way you want it to work, rather than just as a standard package.

Dedicated mold-design tools that simplify intricate modeling tasks provide designers at ComplexaHPE with the control they need to fine-tune complicated geometry.

Cimatron enables designers to work in both surfaces and solids, which is helpful when designing complex surfaces and working with models that include challenging radii — such as those on chamfers and fillets — and multiple radii that connect at varying angles.

“I generally work in solids, but if there is an especially complicated radius that I want to remove, or problems with the CAD we received from the customer, I have the option of addressing those issues by switching to surfaces,” Bunting said. “I can create a surface to be joined up with other surfaces, stitch them together, and switch back to working with a solid model. The ability to work with surfaces allows more fine tuning of complicated models.”

Applied to producing medical components, Cimatron’s surface modeling capabilities can be especially helpful with unique surfaces, such as models of knee implants that reflect the complexity of human bones.

“The software provides all of the solid modeling commands, but you can also generate faces and create all sorts of different shapes,” Capener said. “It gives you the facility to manipulate a surface — to bend it and shape it to whatever degree is needed.”

The ability to visualize tooling in its entirety and analyze mold performance throughout the design process is critical to efficient design. As such, Cimatron’s directional analysis technology helps designers at ComplexaHPE manage undercuts by color-coding solid models to clearly display the directions in which various areas of the final component will be pulled when the tool is opened.

“Using the directional analysis tool, you can see instantly from the color coding if there will be a problem with an undercut or if an undercut has a split direction,” Bunting said. “It’s going to let me know if the part’s not going to come away from the side of the tool.”

Cimatron enables users to customize their design environment by creating their own parameters and setting color-coded alerts, so they know when those parameters are exceeded.

“I work with an offset so that anything that’s less than five millimeters away from a cooling channel will be highlighted in red — and you can set that offset to whatever you choose,” Capener said. “It’s not always possible to remain within that ideal distance, and the system will clearly show me when I don’t.”

ComplexaHPE’s lengthy track record for successfully producing high-precision tooling means that the company works with a large share of repeat customers. When tasked with making modifications to existing customer designs, Cimatron helps to simplify the innately complicated process.

“We can put the new model into our existing tool design and then update the entire model in a way that saves a lot of time,” Bunting said. “The software makes it easy to update the rest of the tool faces to that new part without a lot of manual effort — and that’s a process I don’t think other software could do as easily.”

Cimatron helps experienced designers like Bunting and Capener achieve greater efficiency with everyday tasks and confidence when working on one-of-a-kind challenges.

The software is very quick at doing certain things that only mold designers would need it for. It’s very specialized for this industry, and that’s why I like it.

ComplexaHPE utilizes Cimatron CAD software to design intricate molds for the medical industry, enhancing efficiency and precision in producing complex tooling needed for various medical components.

Stevenson High School's MADE Program, in collaboration with Zero Tolerance and Cimatron, is training the next generation of manufacturers through hands-on experience and industry partnerships to address the skilled worker shortage.

WeForm, responding to growing customer demands, invested in a fully automated production cell integrating 5-axis HSC milling and Cimatron CAD/CAM software for efficient production of high-quality plastic and zinc die-cast parts across various industries.

Everstampi, a family-owned company in Misinto with more than 40 years of experience in plastics mold design, stands out for its innovation and focus on customer service, using CAD/CAM solutions from Cimatron to optimize the production process and ensure complex, high-precision molds.

Classic Tool & Die, leveraging Cimatron's advanced CAD/CAM software, achieved a 75% productivity increase and reduced its carbon footprint, while successfully tackling challenging die design projects and fostering innovation with automotive OEMs.

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Follow us on