Bearing It All

How BNL Bearings have used CADCAM to turn products around faster

Download The ArticleBearings make the world go round - almost literally. These essential mechanical elements are a key ingredient in making sure that objects move the right way, with anything that turns requiring one.

As a result, they’re used in many of the major industries, from automotive to food processing, and have hundreds of thousands of other applications. Without bearings, and the motion that they allow, the world would come to a stand still.

The world leader in producing integrated plastic bearings, BNL Bearings has been at the forefront of designing and manufacturing these rolling element bearings since the company’s founding in 1970. Since then, their processes have been refined and perfected, despite becoming more complex, in order to allow them to produce bearings for an ever-increasing number of global markets and adapt to a constantly changing world.

Picking Plastic

However, with most bearings being made out of metal, BNL’s dedication to making plastic ones begs the question: why would a plastic bearing be preferable?

The answers are manyfold, a key one being that plastic bearings don’t corrode. Naturally, many metals are susceptible to corrosion from water and chemicals, which leads to the premature wear of the bearing, so the bearing and the product it is used in will have a reduced operational life.

As a result, BNL’s plastic non-corrosive bearings are common in industries where water is heavily present, such as shower doors or pool cleaners. Similarly, products that are built for outdoor use will need non-corrosive bearings, because they will be exposed to the elements. For example, plastic bearings used in a wind turbine will be protected from the elements, while bearings used in applications such as yacht and boat rigging will be protected from wear caused by salt water.

BNL’s plastic bearings also boast chemical-resistance, which is particularly helpful when the bearings are used in certain environments. The BNL bearings that are made out of specialist materials, such as UHMWPE and PEEK, are put to use in hostile habitats such as the chemical baths used in LED screen processing, an environment that would cause many metal bearings to fail prematurely. Additionally, chemical-resistant plastic bearings are invaluable in the food industry, where avoiding contamination is vital. Disinfecting the conveyor systems is crucial, so it’s important that the bearings used in the wheels aren’t worn by the chemical disinfectants from the frequent washdowns.

Another reason for opting for plastic bearings over metal ones is the fact that they don’t require lubricant. “Thermoplastics are inherently lubricated, so BNL bearings do not need to be greased,” says BNL’s UK Tooling Manager Dave Clark, a benefit which makes maintenance far easier.

This is particularly useful in the paper path industries, where lubrication could otherwise ruin the paper. Whether it’s an ATM depositing cash or a printer generating hard copies, lubricant can cause the paper to be blemished with unwanted markings, ruining banknotes or hard copies. The issues don’t end there, either, when it comes to printers and photocopiers, because the toner can mix with the lubricant, which creates a grinding paste that then wears the bearing prematurely. With a BNL bearing, these problems can be avoided.

Evidently, plastic bearings that are free of lubrication help to make their products easier and more cost-effective to maintain. It’s a notable benefit and one that, in fact, gave BNL its name - the acronym stands for Bearings Non-Lube. Plastic’s inherent lightness can also contribute to energy efficiencies. BNL’s plastic bearing designs are generally much lighter than a steel equivalent, but using their trademark integrated design techniques to remove components and fixings from the product, custom designed bearings can be up to 50% lighter than an alternative multi-component solution. In reducing weight, they reduce torque to rotate on start-up and in operation, which means that smaller, less expensive motors can be used. Meanwhile, using lighter weight bearings in vehicle steering columns helps to lower the vehicle’s overall weight, helping contribute to a reduction in its carbon emissions.

As if all that wasn’t enough, BNL’s plastic bearings can offer plenty of financial benefit too. For one thing, plastic materials can be less costly than a metal equivalent like steel. On top of that, the fact that BNL can design and mould their bearings allows them to combine mating parts into one product, reducing component count for their customers’ products. With fewer components, there are fewer costs, as well as reduced assembly steps and time. As for their application, the lighter and more energy efficient bearings mean that the products they’re used in can be more compact, and this helps save money on inventory costs and logistics too.

As you can see, BNL’s primary selling point of moulding their plastic bearings - a form of comprehensive control that allows for improved performance, whole system cost reductions, simplified maintenance, and much more - is incredibly beneficial. But what are BNL’s moulding techniques?

Moulding For Precision

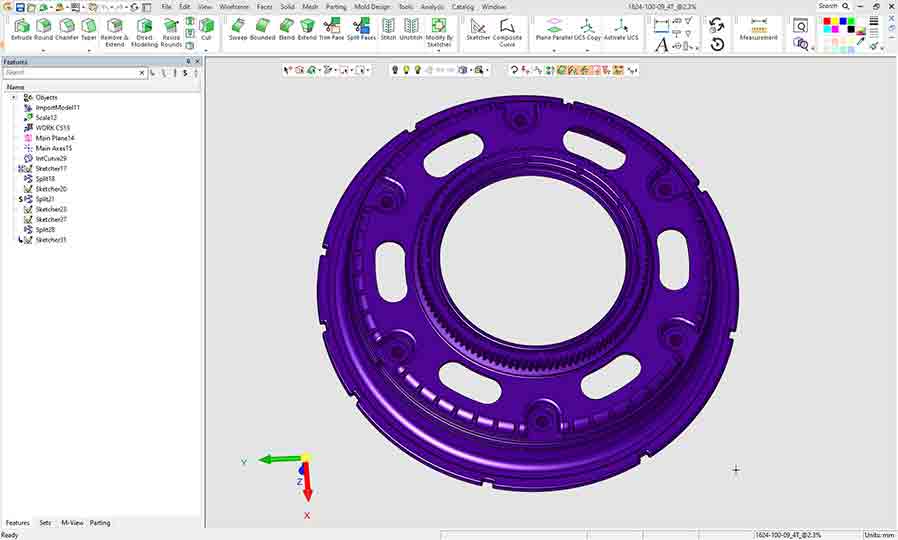

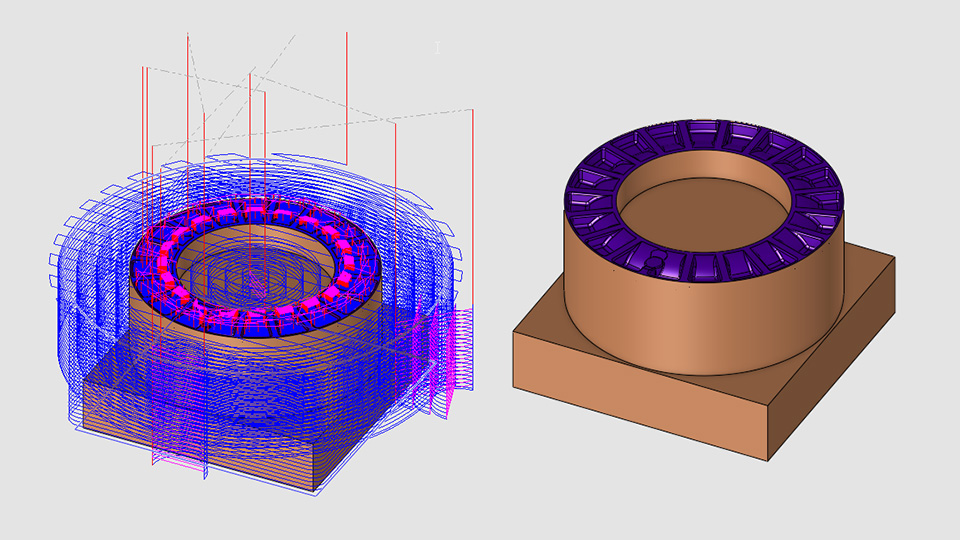

Injection moulding is the technique of choice for BNL - and one that they’ve perfected for bearing manufacture. “About 99%” of their products are injection moulded, says Clark, with the 1% that aren’t simply being such low volume that they don’t justify the tools.

The injection moulding process involves molten plastic being squeezed into a mould at high pressure, before water cools it and the plastic solidifies. It’s a process that allows for extremely high precision products to be made, which is crucial when dealing with bearings since they can come in all sizes. For example, an extremely small bearing will need to be intricately designed in order for it to work properly.

However, before the injection moulding process can begin, a design for the product and the mould needs to be created - which is where Cimatron software comes into play.

In-House Tool Design

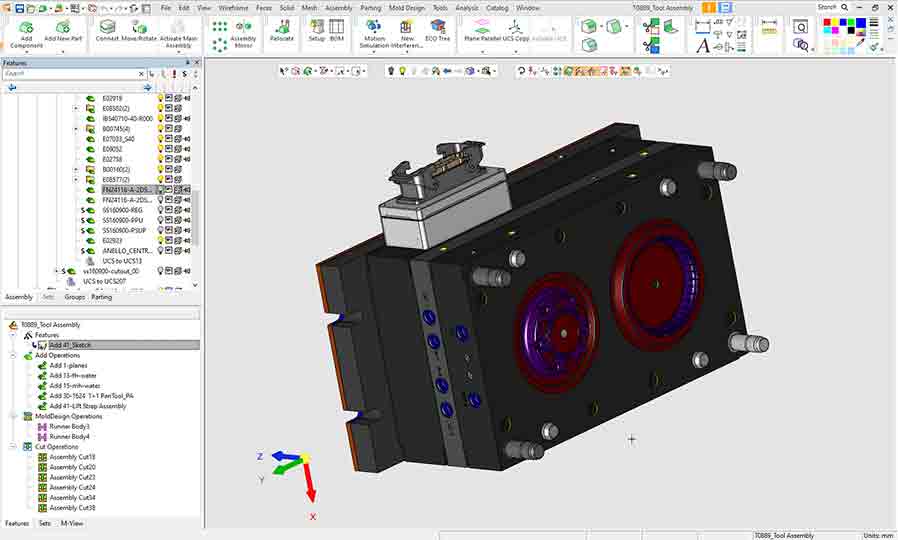

BNL has found immense success with Cimatron CADCAM software since first embracing it in 2006, and that shows no signs of changing. “Previously to BNL doing its own in-house designs,” says Clark, “it used to purchase all its tool designs externally.”

Though this was an ample way of operating, they found that relying on a toolmaker’s tool design had its shortcomings, because the toolmakers were simply less familiar with the processes and precision needed to manufacture moulded plastic bearings than BNL. Naturally, when the moulding process requires as many features and as much precision as injection moulding, familiarity is vital.

Additionally, Clark notes that “we got better control of the tool design by doing our own in-house tool designs”. Control is important, allowing BNL to get exactly the dimensional development they want, and “we do all the programming in Cimatron.” From adjusting the tool design, which is done with the Mold Design package, to even the 3D CAM package that’s used for transferring to the machines on the shop floor, Cimatron provides an intuitive, efficient way to work.

We found that the Cimatron package targeted plastic pack design and plastic tool design in a way that gave the company a much easier, much quicker process than other packages at that time.

Selecting Cimatron over other CADCAM softwares was the result of reviewing a number of different ones, as well as a recommendation from one of BNL’s toolmakers. Says Clark, “we found that the Cimatron package targeted that plastic pack design and plastic tool design” in a way that gave the company a much easier, much quicker process than other packages at that time.

But does it still hold up after all these years? The answer is a resounding yes. BNL regularly talks to other sub-contract designers who also use Cimatron, and the consensus is that it still provides a far quicker way of doing things.

The Future

BNL’s plastic bearings are essential to an enormous range of industries. From conveyor systems to conference cameras, and even smart controls to dishwashers, BNL’s print can be found everywhere and their reach will only expand.

One of the primary industries is the automotive world, where bearings are crucial to many parts of a vehicle, such as steering columns and infotainment control. However, with so many vehicles now moving to LCD touchscreens, you might imagine that there will be less of a need for knobs and their bearings - not so.

“Market research by the big OEMs have shown that drivers don’t like the fact that you have to take your eyes off the road to operate the screen, and there are recognised safety concerns in the industry,” says Clark. “Drivers still prefer the knobs and switch-type situation.” This is where one of BNL’s recent innovative ventures arises.

Working closely with leading corporation Microchip Technology Inc., BNL has designed “a control knob that can be positioned and fixed to a capacitive screen, where it then allows the driver to operate the screen menus and selections via turning and pressing the BNL control. Rather than needing to swipe and touch specific areas of the screen, which would require the driver to look away from the road, the BNL control knob rotates through the menu options and provides haptic feedback to the driver, who can then select their option with a push.”

Known as “Knob-on-Display”, BNL’s design proves the desire for rotational function will continue but that bearing designs will need to adapt with the advancements of more digital technologies - and BNL’s integrated custom bearing designs are already advancing towards this future.

It’s an innovative concept from a company rife with new ideas, and one that is able to be brought to life with Cimatron software and a team of highly skilled engineers.

Written by Rupert Morgans-Wicks, CDG 3D TECH