Cimatron electrode accelerates electrode production as an all-in-one solution for design, burning, and machining.

Download Brochure

Cut electrode design time by 80% with advanced tools for each step of the design process.

Check electrode and holder designs for collisions with parts and fixtures.

Automatically select of user-defined milling strategies based on electrode geometry.

Automatically generate inspection drawings for electrodes that enable shop-floor staff to verify dimensions prior to burning.

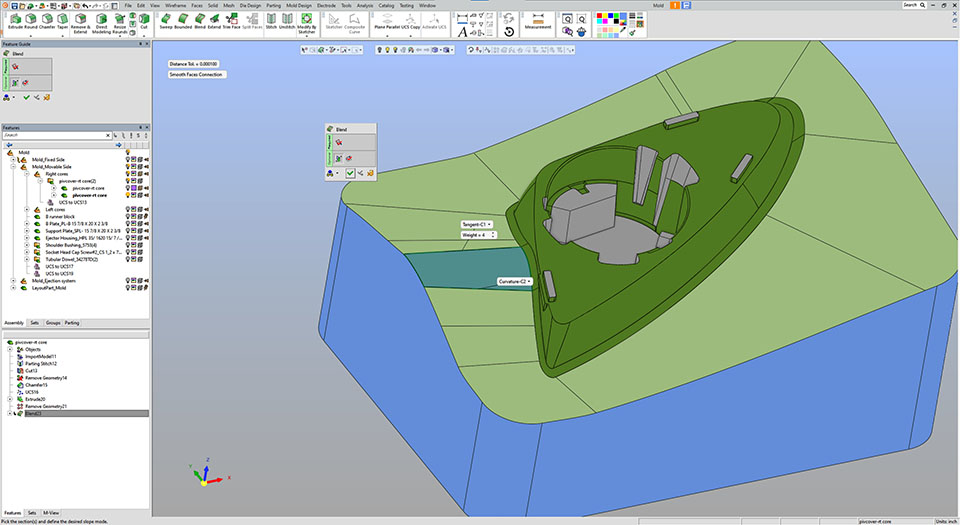

Cut electrode design time by 80% with versatile surface creation capabilities and advanced tools for each step of the design process. Cimatron simplifies the selection of burning surfaces and the generation of holder and blank geometry, as well as the creation and reuse of electrode design templates for greater efficiency.

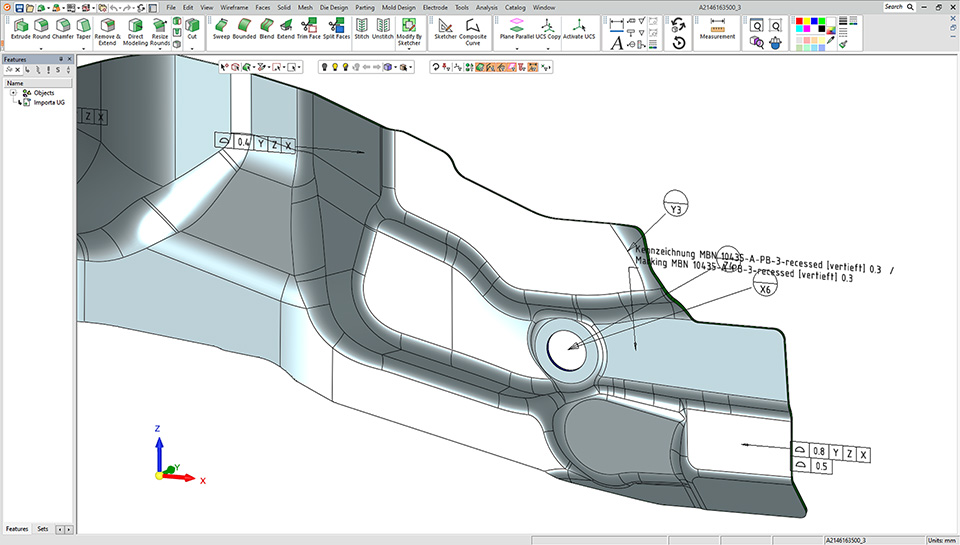

Quickly define error-free burning processes for each electrode and burning path, including spark gaps, 2D and 3D orbiting, and rough offsets. Automatically generate inspection drawings for electrodes that enable shop-floor staff to verify dimensions prior to burning. Generate setup and burning sheets for each electrode, including corresponding locations and rotations, and drawings of the entire EDM process.

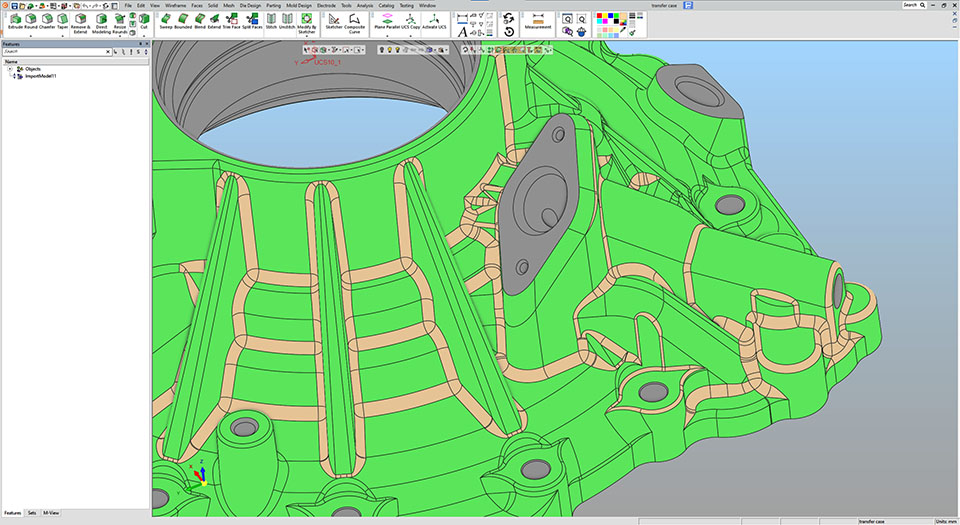

Create comprehensive 2.5-axis to 5-axis machining operations at the click of a button. Cimatron accounts for burning parameters like spark gaps, 2D and 3D orbiting, and rough offsets for error-free, accurate machining. Colors can be automatically assigned to components for design validation and to simplify the selection of geometry used in machining templates. Process templates can be easily created and reused, enabling the automatic selection of user-defined milling strategies based on electrode geometry.