Four industry trends driving change within the technology

CAD/CAM updates and features have largely been focused on enhanced productivity and increased digitization. Research and development in the CAD/CAM space is influenced by a number of factors, including the latest machining technology, Industry 4.0, robotics, and market trends.

1. Advanced Machining Technology and Demands

Whether it is a tool and die manufacturer, production machining facility, or small job shop, the market demands have changed significantly over the last few years. Efficiency, productivity, and price are driving manufacturing trends.

“Many [manufacturers] are now facing shorter lead times,” said Dan Marinac, product strategy and marketing manager, Cimatron, Burlington, Canada. “For example, what used to take 16 to 20 weeks is now expected to be delivered in just 10 weeks. [Manufacturers] must find ways to differentiate themselves from offshore companies to stay competitive in this market. One way to do this is to become more efficient and innovative in their design and manufacturing processes.”

To meet these tighter time frames, CAD/CAM developers are forced to find new tools and features to speed up the time it takes to design and manufacturer products.

For example, features like part analysis and repair for problematic geometry, automated parting line/surface, automated core/cavity extraction, smart catalog component placement, automation for cooling line creation, plastic flow prediction, simulation, warpage analysis and compensation, automated electrode machining, NC template application, and automated gun drilling have all been developed to ensure that mold/die manufacturers are able to shorten the time needed to produce new tooling designs.

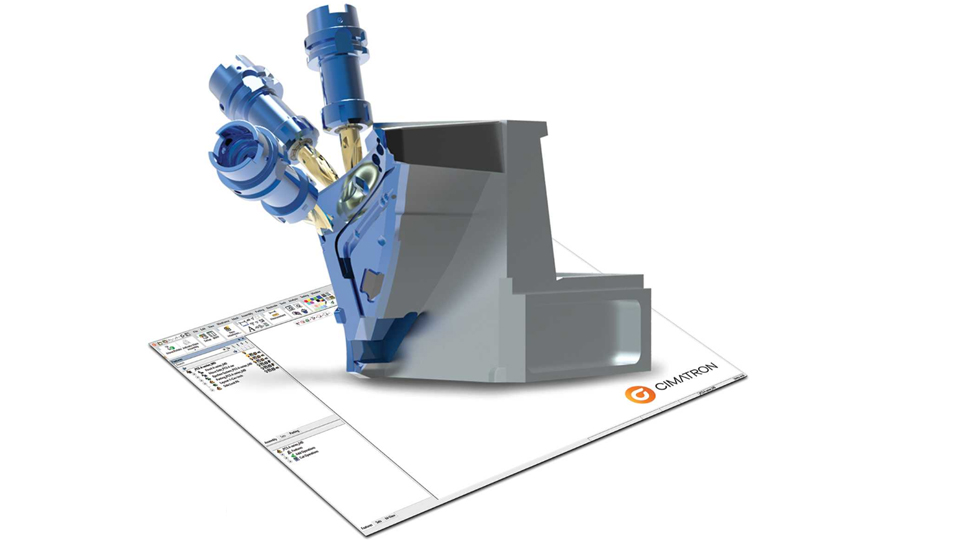

Outside of tighter lead times, manufacturers also are seeing a shift in the technology. For example, 5-axis machining has become increasingly popular.

“5-axis machining centers are being increasingly used because of their ability to access more features of a workpiece and machine more aggressively with shorter tools and a sturdy machine construction,” said Marinac. “This has reduced the need for EDM and hand benchwork.”

This technology trend directly affects the functionality of CAD/CAM. Today’s software has been updated to include modules and features to enable efficient 5-axis machining and material removal simulation for medical, aerospace, and other complex parts. For example, some software offers access to library of proven posts for any 5-axis machine and controller, including on machine inspection and probe toolpath creation.

Read the whole article at Canadian Metalworking here: https://www.canadianmetalworking.com/canadianmetalworking/article/automationsoftware/modern-day-cadcam