Cimatron CAM provides powerful tools for the efficient programming of 2.5-axis to 5-axis CNC machine tools, including specialized strategies for machining molds, plates, dies, and discrete parts.

A hybrid CAD environment and variety of design tools help quickly prepare solid models for production

Generate safe and accurate toolpath, and take advantage of specialized strategies for milling and drilling

Machine with confidence using simulation representing machine kinematics, fixtures, and workpieces

A hybrid CAD environment enables designers to easily repair models and modify designs using a combination of wireframe, surface, and solid functions. Specialized design tools make it easy to apply drafts and rounds, remove or modify rounds, cap holes and slots, and extend surfaces. Tools that detect and analyze changes to geometry help increase confidence in designs.

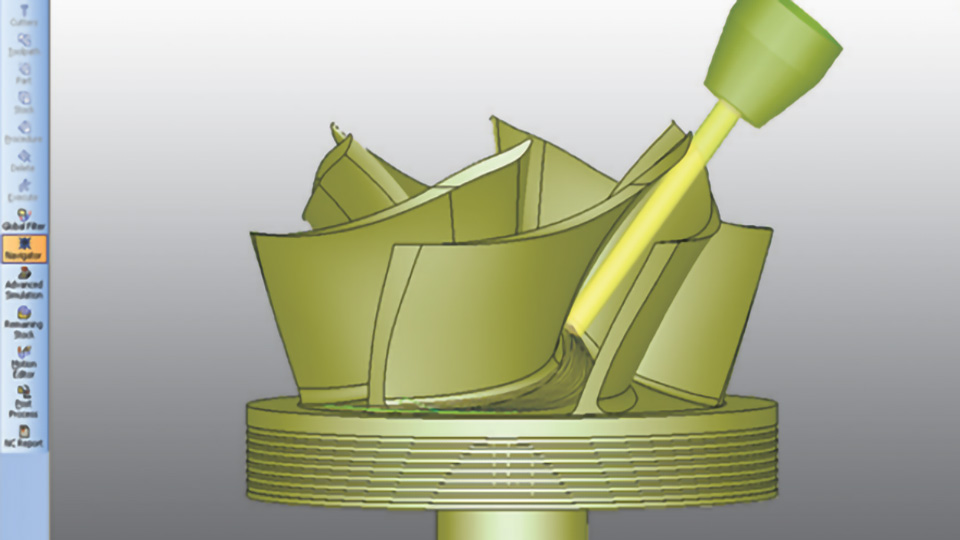

Improve programming efficiency with specialized machining strategies that allow CNC programmers to retain complete control over all 5-axis machining operations. Cimatron provides strategies for machining complex blades, impellers, blisks, turbines, and more. A comprehensive library of proven post processors for 5-axis machine tools and controllers helps ensure accuracy and efficiency.

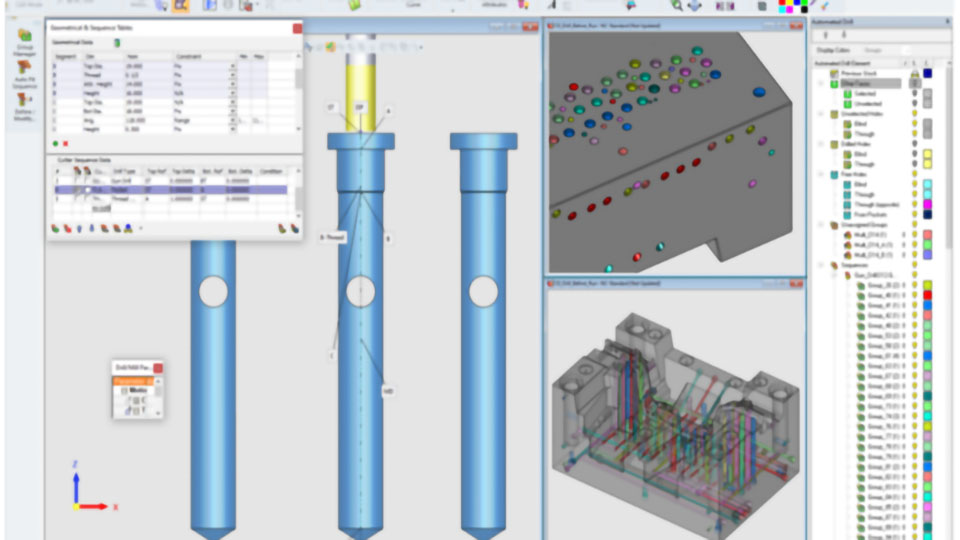

Cimatron CAM provides a rough pocketing strategy that simplifies high-speed machining (HSM) operations and the 2.5-axis machining of open and closed pockets. Rapid material removal makes machining open pockets more productive, while templates that help automate pocket and profiling operations increase programming efficiency. Automated drilling functions, including hole and stock recognition, cut programming time by up to 90 percent.

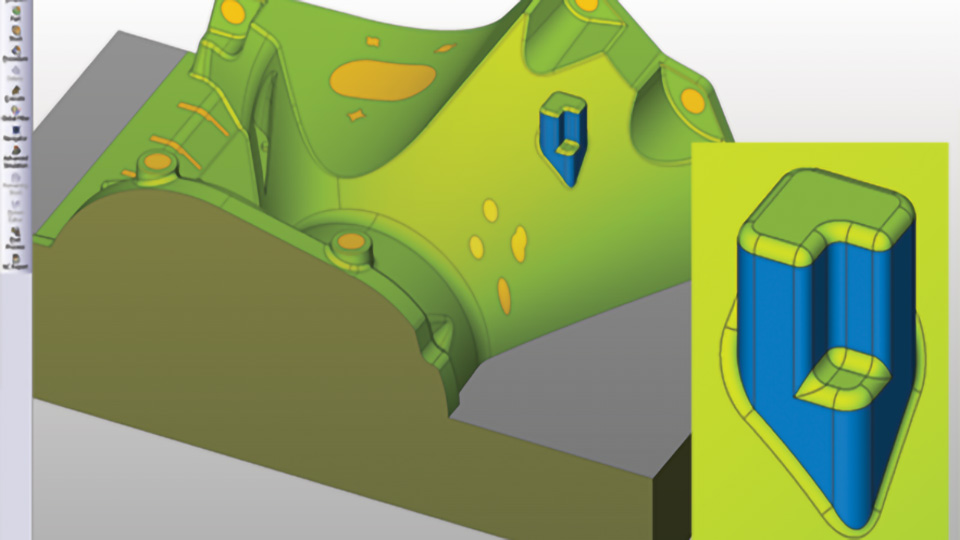

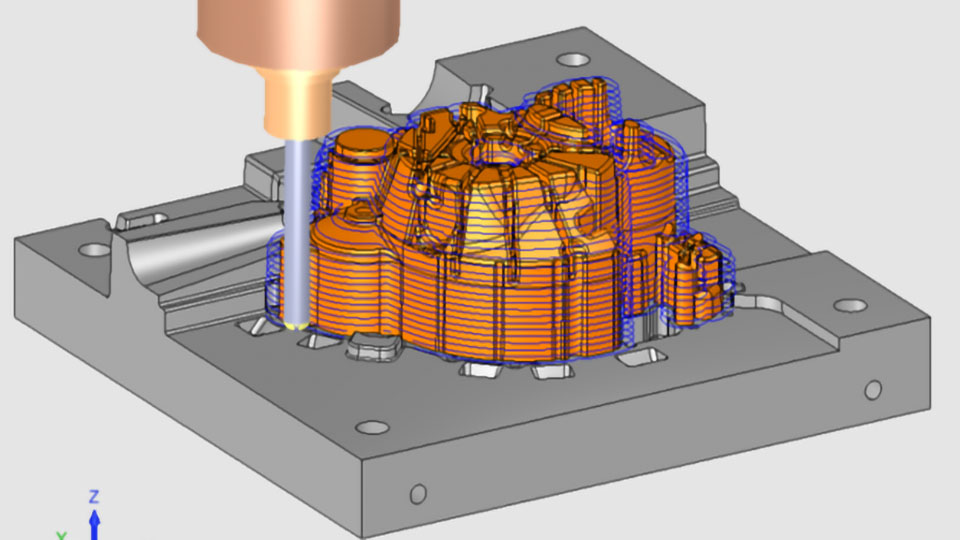

Increase productivity with roughing strategies that enable the safe and efficient removal of material at high rates. When roughing is complete, superior surface quality can be achieved with strategies for 3-axis to 5-axis finishing, cleanup, and rest material operations. Roughing and finishing capabilities include dedicated functionality for electrodes and micro milling.

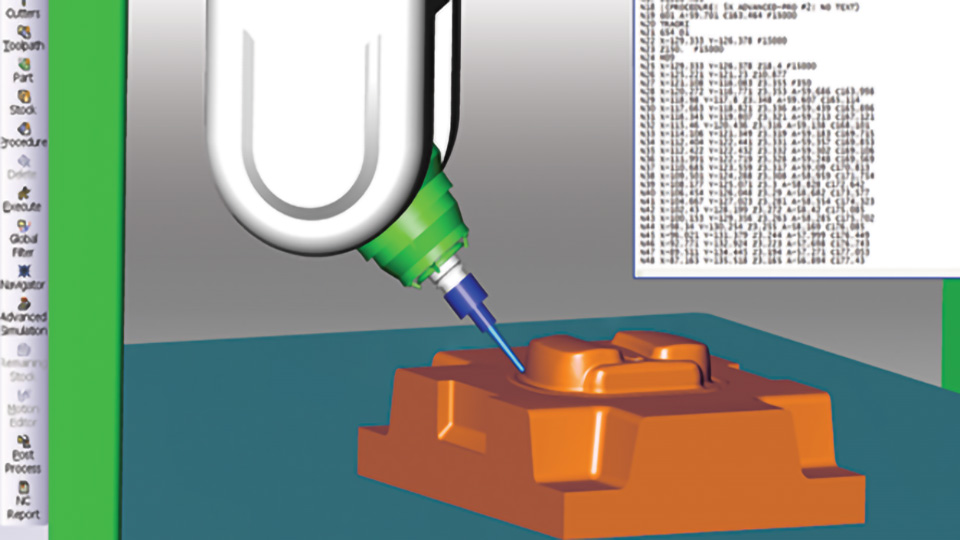

Multi-axis toolpath simulation and comprehensive gouge and collision detection capabilities help manufacturers machine with confidence. CNC program simulation includes detailed graphical representations of machine kinematics, workpieces, and fixtures. Collision and gouge detection verifies the safe and efficient operation of machine tools, fixtures, stock, workpieces, cutting tools, and tool holders.

Follow us on